A Look at Iran’s Automotive Industry During the Iran-Iraq War

As Iran’s economy today grapples with instability stemming from the recent 12-day conflict with the Israeli regime, many economic officials and industry leaders are turning to the lessons learned during the eight-year Iran-Iraq War. One notable example is the automotive industry, which managed to survive those difficult years through resilience and a commitment to domestic engineering—overcoming falling production rates and the withdrawal of foreign partners by entering the realm of local parts manufacturing and localization.

As Iran’s economy today grapples with instability stemming from the recent 12-day conflict with the Israeli regime, many economic officials and industry leaders are turning to the lessons learned during the eight-year Iran-Iraq War. One notable example is the automotive industry, which managed to survive those difficult years through resilience and a commitment to domestic engineering—overcoming falling production rates and the withdrawal of foreign partners by entering the realm of local parts manufacturing and localization.

Resilience Amidst Conflict: How War Shaped Iran’s Auto Sector

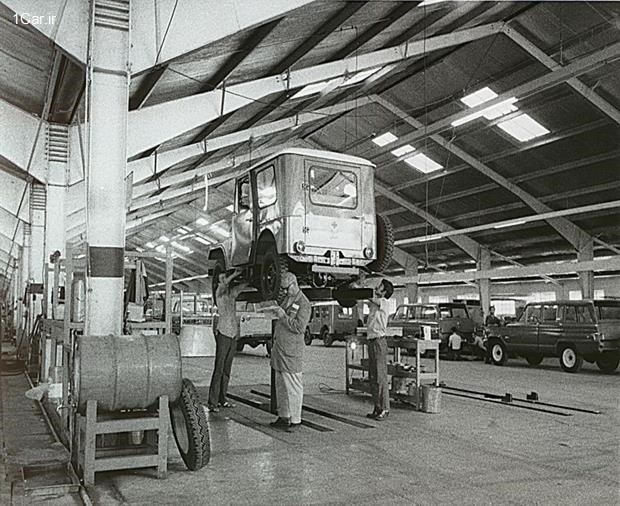

Between 1980 and 1988, during the Iran-Iraq War, Iran's automotive industry faced immense challenges. One of the most significant setbacks was the drastic decline in production. Auto manufacturers such as Iran Khodro and SAIPA found themselves unable to operate at full capacity due to a lack of parts, international sanctions, and damaged infrastructure. In certain years during the war, vehicle production fell to less than half of what it was prior to the 1979 Islamic Revolution.

Adding to the difficulty was the abrupt cessation of collaborations with major European carmakers such as Peugeot, Citroën, and Renault. For example, Iran Khodro, which had been assembling the Paykan with support from the British firm Talbot, suddenly had to turn to domestic parts suppliers due to the limitations on imports.

In response, both Iran Khodro and SAIPA adopted simplified production lines and lower-quality local components to keep operations afloat. While the initial output lacked the refinement of imported components, it was a crucial step in the development of Iran’s auto parts industry.

Limited Resources, Military Priorities, and Black Market Growth

During the war, government funding was heavily directed toward the defense sector, leaving auto manufacturers with limited resources. Access to raw materials such as steel and industrial plastics became increasingly difficult.

As a result, vehicle production was prioritized for military, government, and emergency services, including use by the armed forces, Red Crescent, and ambulances. Private vehicle production was severely restricted, and prices for passenger cars in the market soared.

This shortage of supply fueled a thriving black market, where foreign-made vehicles were smuggled in and sold at astronomical prices.

Key Models of the Era: Paykan, Renault 5, and the Decline of the Zhian

The Paykan, assembled by Iran Khodro, became the mainstay of domestic transportation—used widely in public services, government fleets, and even military logistics. However, after ties with Talbot were severed, sourcing engine and transmission parts became a major challenge.

To tackle this, Iran Khodro began to develop domestic capabilities, which led to the strengthening of local suppliers such as IDEM Tabriz (engine production), Charkheshgar Tabriz (transmissions), and Sazehgostar (component manufacturing). Many components of the Paykan that were once imported were now being produced domestically, albeit initially at lower quality. Nevertheless, this effort laid the groundwork for the growth of Iran’s parts industry in the 1990s.

SAIPA, meanwhile, continued to assemble the Renault 5 in the early years of the war. However, due to the eventual end of cooperation with Renault and the halted import of critical parts, this model was gradually phased out. Another SAIPA model, the Zhian—a simple, affordable car from the 1970s—was also removed from production early in the war.

In the face of limited product lines, SAIPA shifted toward utility vehicles and pickups, which led to the assembly of the Nissan pickup, a model that served in various government and military institutions including the IRGC, the army, and Jihad Sazandegi (Construction Jihad).

The Engineering Spirit That Drove Localization

What clearly emerges from the analysis of Iran’s automotive industry during the Iran-Iraq War is the determination and ingenuity of Iranian engineers, who managed to redesign parts, create molds, and even build essential tooling with minimal resources. This period was instrumental in shaping the expertise of many key industrial managers who would later drive growth in the post-war years.

In support of local manufacturing, the government implemented policies such as tight restrictions on car imports and increased tariffs, which provided a protective buffer for domestic automakers to survive and recover.

The War’s End: Planting Seeds for Future Growth

With the end of the war in 1988, the automotive sector finally had the chance to rebuild and modernize. Many of the technological and organizational foundations laid during wartime paved the way for significant developments in the 1990s. The seeds of Iran’s contemporary automotive and parts industries were, without doubt, sown during those turbulent years—a subject we will explore further in upcoming reports.