What will the Future of Car Tires look like?

The complex ingredients that make modern tires safe also make them a pain to throw away.

Khodrocar - Every year, the Michelin tire company gathers the smartest minds in transportation for Movin’On, three days of panels, presentations, and people wearing lanyard ID tags. It’s a tire convention—and it’s fascinating. This year, engineers at Michelin showed off a plan to make new tires from 80 percent renewable materials like wood, straw, or beets (seriously).

Each year, automobiles produce 246 million waste tires in the United States alone.

Why does Michelin spend more than $800 million a year researching sustainability so it can make tires out of root vegetables? Because the modern tire—more specifically, its disposal—is a filthy business. Each year, automobiles produce 246 million waste tires in the United States alone. How to reduce that astonishing number is a challenge so pressing that it has created its own industry dedicated to recycling efficiency.

What’s Inside a Tire?

19% Natural rubber, usually from trees in Southeast Asia

38% Synthetic rubber (butadiene, styrene, halobutyl rubber) and additives, to prevent damage from ozone and oxygen, and to promote curing

4% Synthetic-polymer fabric belts (nylon, rayon, and aramid), for reinforcement

12% Wire (high-carbon steel), for more reinforcement

26% Fillers (carbon black, silica)

Where Do Dead Tires Go?

26% Ground into filler for asphalt and insulation.

11% Dumped into landfills, where a tire takes hundreds of years to decompose.

7% into road beds, barriers, retaining walls, and other civil- engineering uses.

7% Recycled into things like playground surfaces and tire swings.

49% Burned for fuel. Tire rubber has more energy (Btu) than coal but, like any solid fuel, tires burn dirty, requiring energy to clean the particulates.

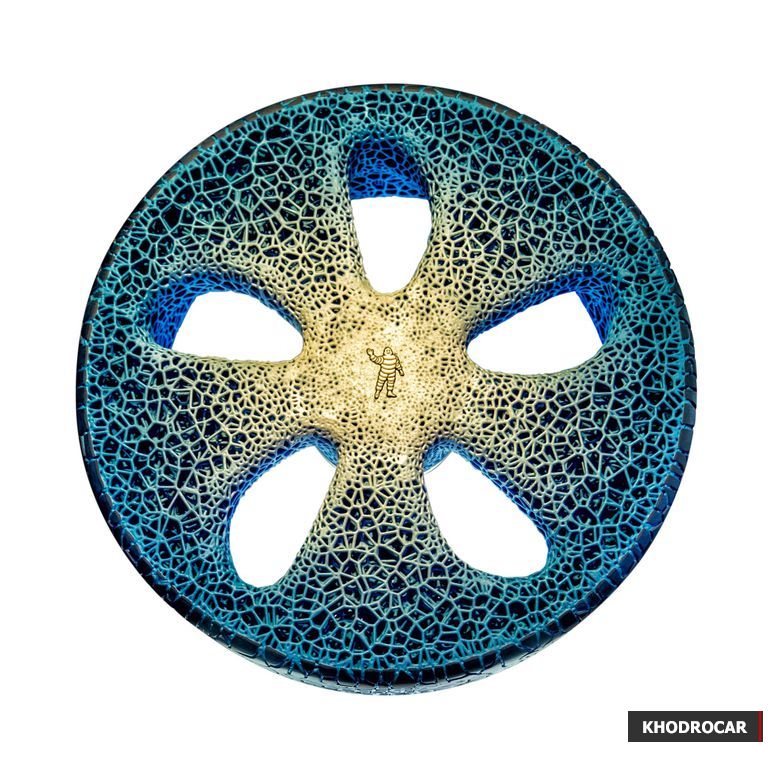

The Printable Tire of the Future

Michelin’s concept tire is 3D-printed, renewable, biodegradable, and airless. Drivers would pull into a docking station and have the treads reshaped according to road conditions.

Source: Popular Mechanics

Latest News